Description

AED offer over 20+ years in-house

manufacturing rollers / drums

We have a dedicated drum manufacturing facility, with

turning capacity of up to: 457mm

diameters x 2.4m Long

We have a modern machine shop boasting: two 5axis machine

centres, three 2axis cnc & one Dean Smith & Grace Conventional lathe

Highlighted are popular drum diameters

|

|||||

|

Roller tube

diameters below, included CDS, CHS & HFS Tube |

|||||

|

50.80<108 |

108<146 |

146<203 |

203<273 |

273<343 |

355<470 |

|

60mm |

114mm |

152mm |

219mm |

279mm |

368mm |

|

76mm |

121mm |

159mm |

229mm |

292mm |

394mm |

|

82.5mm |

127mm |

168mm |

244mm |

298.5mm |

406mm |

|

89mm |

133mm |

178mm |

254mm |

305mm |

419mm |

|

101.6mm |

139.7mm |

193.7mm |

267mm |

324mm |

445mm |

|

108mm |

146mm |

203mm |

273mm LG |

343mm |

457mm |

|

Remember, our max. roller length 2.4m |

|||||

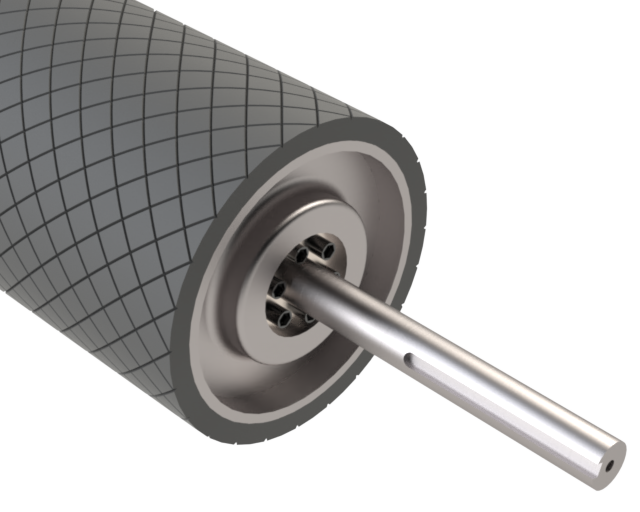

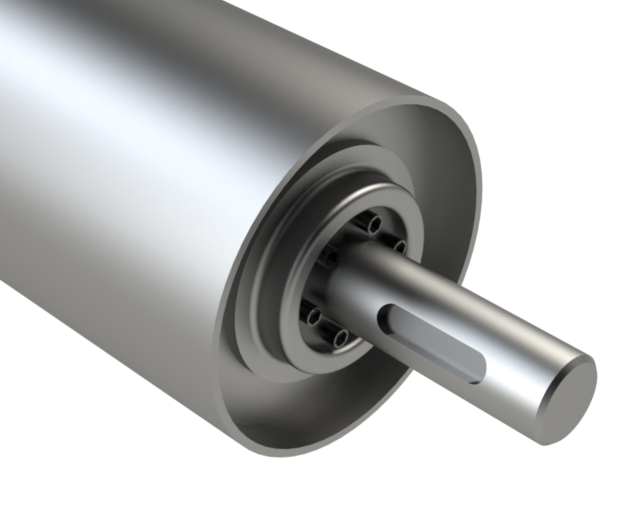

Design:

- Smooth

machined surfaces provide maximum belt protection.

- Hubs

and end disc are accurately machined to ensure concentricity.

- Drums /Machined

rollers are available with a parallel or crowned*

- Steel Drums are now fitted with KEYLESS CLAMP, for cost effective maintenance with superior performance Removeable axle via clamping ring / Youtube

- Lagging

(rubber/polyurethane covering) can be provided to increase traction

between belt and pulley