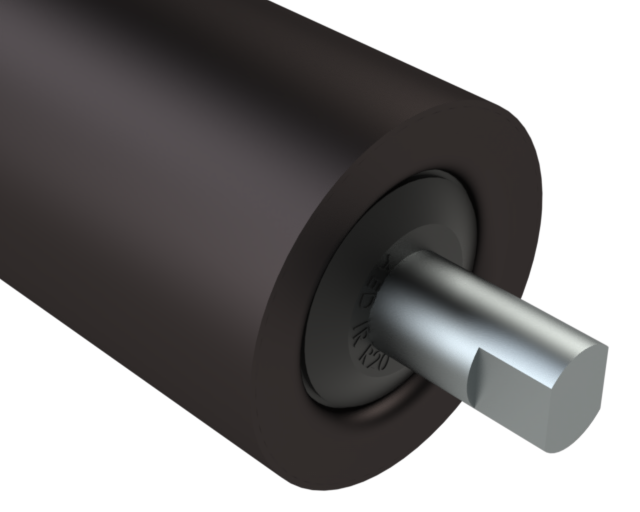

Description

IR5500 are ideal for use in industries such as Bulk Handing: mining, agricultural, construction, and many others.

IR5500 rollers have minimum IP61 rating (Dust tight and protection against falling water). Depending on roller build and bearing choice, certain rollers will offer <IP64 (Dust tight and protection against sprayed or splashing water)

They

are engineered to withstand heavy loads, harsh environments, and extreme

temperatures, making them suitable for even the most challenging applications

The

IR5500 series are made here, in our West Midlands factory. These are ideally

made in 1 to 2 weeks!!

We also make Transom sets

|

Roller Type |

Tube Dia & thickness |

Axle dia |

Tube Finish

Options. Default

self-colour. BZP & painted are optional extra |

|

IR51 |

50.8 x3.0 |

20 | 25 |

Self Colour | BZP |

|

IR60 |

60 x3 |

20 |

Self Colour | BZP | Spray Black |

|

IR63 |

63.5 x3.0 |

20 | 25 |

Self Colour | BZP | Spray Black |

|

IR70 |

70 x3.0 |

20 |

Self Colour | BZP | Spray Black |

|

IR76 |

76 x3.0 |

20 | 25 |

Self Colour | BZP | Spray Black |

|

IR803 |

80 x3.0 |

20 | |

Self Colour | BZP | Spray Black |

|

IR89 |

89 x3.0 |

20 | 25 | 30 |

Self Colour | BZP | Spray Black |

|

IR4 |

101.6 x3.0 |

20 | 25 |

Self Colour | BZP | Spray Black |

|

IR108 |

108 x3.0 |

20 | 25 | 30 |

Self Colour | BZP | Spray Black |

|

IR127 |

127 x3.0 |

25 | 30 |

Self Colour | BZP | Spray Black |

|

IR133 |

133 x3.6 |

25 | 30 |

Self Colour | Spray Black |

|

IR6HD9 |

140 x9.0 |

25 | 30 |

Self Colour | Spray Black |

|

IR159 |

159 x4.5 |

30 | 35 | 40 |

Self Colour | Spray Black |

|

IR168 |

168 x6.0 |

35 |

Self Colour | Spray Black |

|

Range |

Load Rating |

Bearing Operating Temperature |

Material Options |

Applications |

|

IR5500 |

High |

Standard -20 to 120°C Extreme -40°C |

Mild Steel, painted, Zinc Plated. |

Heavy-duty applications, high-speed conveyors, manufacturing, mining,

and quarrying |