Description

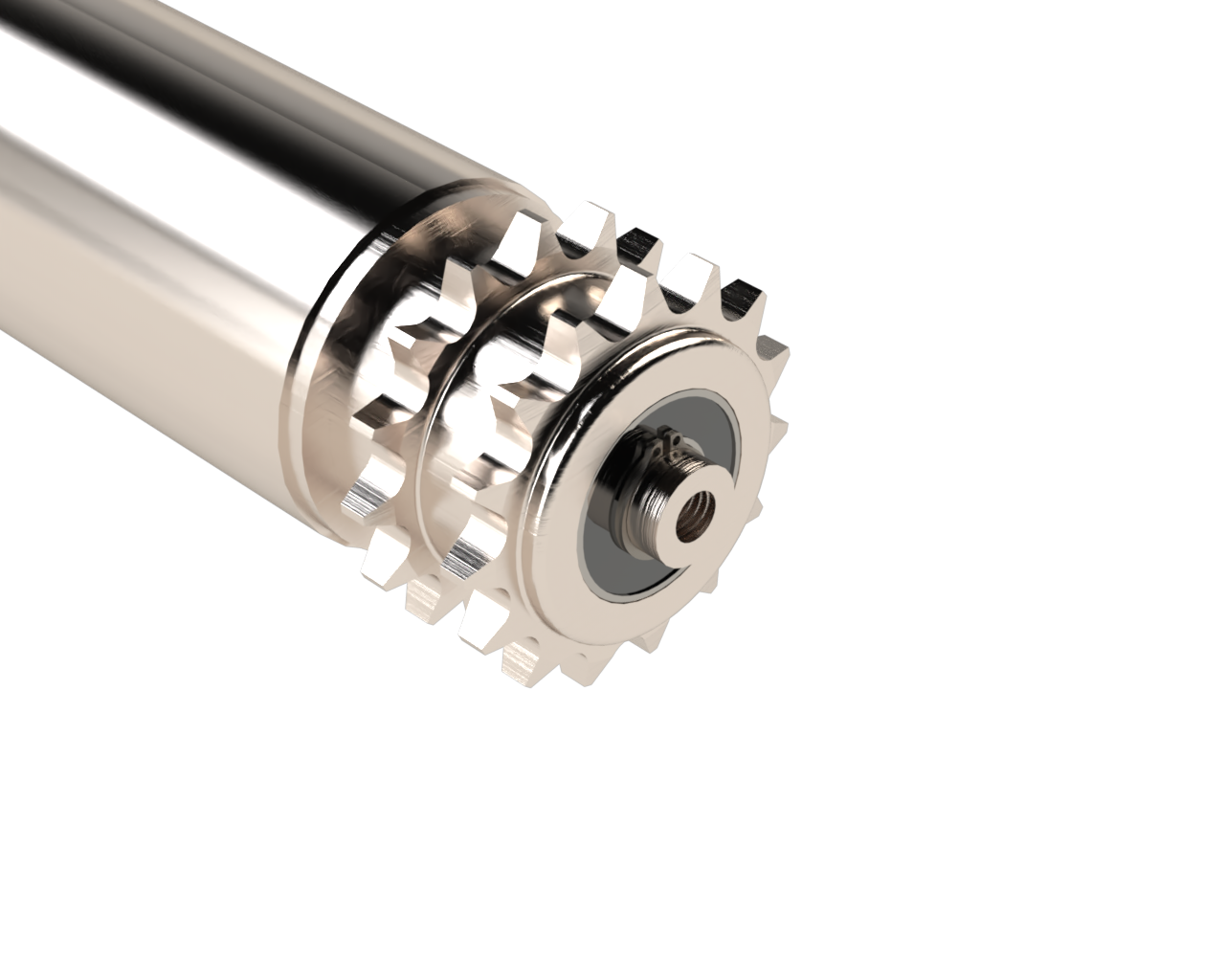

5/8”p Fixed Drive Roller with double or simple Steel sprockets

CDR3900 Series sprocket rollers are for 010b chain driven conveyor and are fitted

with simple or double steel sprocket.

Sprocket rollers are for chain driven conveyor such as:

·

Heavy duty pallet distribution

·

Indoor /outdoor

·

Cold Store* please clearly state on

enquiry/order if required for cold storage with ambient working temperature.

All rollers are fitted with welded steel sprockets for

fixed drive and have minimum tube thickness 3mm.

Roller finish is generally BZP steel. Other options

include:

·

Black Oxide

· Self-Colour steel

·

Stainless (excludes sprocket)

·

Rubber covered.

Optional Extras

Pallet guide discs – see sheet BS guide discs.

|

Dimensional Terminology |

AED Acronym |

Industry Acronym |

Technical Definition and Procurement Search Intent |

|

Between Brackets/ between Frames |

OA/BB |

BF EL AGL |

The distance between the inner walls of the side

frames. The primary, most reliable metric for determining correct roller

length compatibility. |

|

Sprocket chain arrangement |

SIM DSIM DPLX |

SIMPLEX, DOUBLE SIMPLE, DUPLEX |

The chain can be 1x Simple, 2x Simple or Duplex

chain arrangement |

|

Effective Tube Length |

ETL |

RL |

The measurement from the outermost point of the

bearing on one side to the outermost point of the bearing on the opposing

side, used when frame measurement is impossible. |

|

Overall Axle Length |

OA |

OAL AGL AL |

The total length of the internal shaft that supports

the roller tube and mounts directly into the pre-drilled conveyor frame holes. |

|

No of Teeth & Chain Pitch |

ZP |

ZP |

The total number of sprocket teeth and the chain

pitch, this would be 06B, 08B, 10B, 12B |

Remember, We manufacture our own sprockets so we can also offer

specials made to suit your existing profiles in; Simplex, Double simplex,

Duplex and even Triplex profiles

Go to downloads for additional information