Description

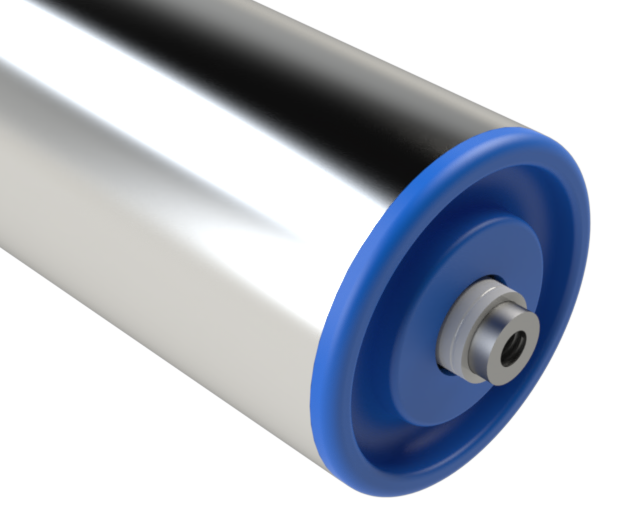

LD100-RG series lightweight BZP steel conveyor rollers fitted with free rolling bearings

developed carton transfer with minimal effort. Rollers will made to order, quickly

and despatch to UK & EU with a growing interest to rest of world where

speed, quality and adaptability is key

- Manual assembly lines (light goods)

- Packing lines

- Lowload/Lightweight Conveyors

- Wet Areas (specify BZP / Stainless axle only)

- Warehouses

- Not recommended for under belt

applications

LD100-RG steel rollers are light duty and spin freely and corrosion resistant bearings which require no further lubrication during operational life.

Range | Load Rating | Operating Temperature | Material Options | End Bearings | Applications |

LD 100 | Light | 0 to 40°C | BZP Steel | Markes plastic KTR.01 oiled | Roller conveyor systems, manual assembly lines, end of line packing, warehouses, and Food process |

AED Rollers are exclusively

UK made, fully guaranteed with certificate of UK Origin. to suit customer requirements

|

Dimensional Terminology |

AED Acronym |

Industry Acronym |

Technical Definition and Procurement Search Intent |

|

|

Between Brackets/ between Frames |

BB |

BF EL |

The distance between the inner walls of the side

frames. The primary, most reliable metric for determining correct roller

length compatibility. |

|

|

Overall Bearings /Over Cones |

OB |

OBP OAC |

The measurement from the outermost point of the

bearing on one side to the outermost point of the bearing on the opposing

side, used when frame measurement is impossible. |

|

|

Overall Axle Length |

OA |

OAL AGL AL |

The total length of the internal shaft that supports

the roller tube and mounts directly into the pre-drilled conveyor frame holes. |

|