5 Reasons to Add Warehouse Conveyors to Your Factory or Manufacturing Plant

Making things is hard. Making lots of things and keeping track of all those things is even harder. That’s why factories use a lot of automation to streamline the production process.

Warehouse conveyors are an example of such automation, and they can be used effectively in almost any factory.

Warehouse Conveyors help companies move materials, finished goods, or anything else necessary to keep operations moving smoothly.

Even if you don’t have a manufacturing plant just yet, there are many reasons why adding conveyors could benefit your business in the long run. Let’s take a look at five key benefits of using warehouse conveyors in your production processes.

It’s a simple, reliable way to move materials

Warehouse conveyors have been used for decades, and for a very good reason.

They provide a simple, reliable way to move materials around a production facility. That’s why they are often used in places where you need to move lots of materials that are heavy or awkward to handle.

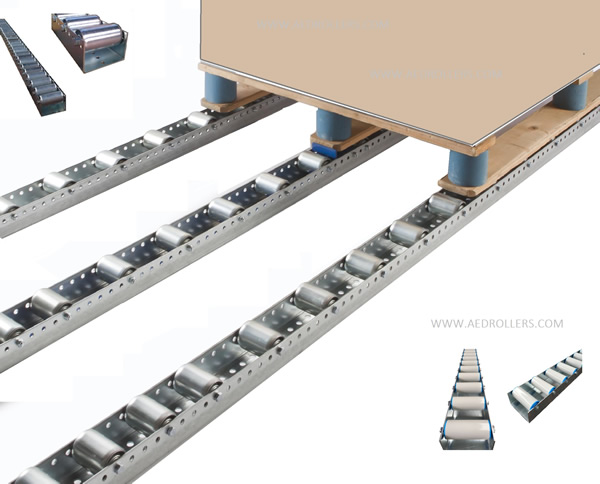

There are many different types of warehouse conveyors, so you can choose the one that will best meet your needs. They come in a variety of widths and lengths, as well as different materials.

Depending on the size of your factory, you can choose a conveyor that connects multiple machines so that you can move materials more effectively.

You can easily track the movement of goods

Since the conveyor is a central piece of equipment in a lot of production facilities, it makes monitoring the movement of goods much easier.

You can track the flow of materials, finished goods, and products in various stages of production. If you’re using a computer-based production system, you may be able to use sensors to track the movements of the conveyor automatically.

This way, you don’t have to manually track everything. And this is crucial when you’re running a large operation.

Warehouse Conveyors help you automate your assembly line

Depending on the type of assembly line you have, you may be able to install conveyors to automate your assembly line.

It’s important to note, though, that not all assembly lines are suitable for automation. The most suitable assembly lines are those that produce small lots of homogeneous goods.

Depending on your industry, this may or may not apply to you. But if it does, you may be able to automate your assembly line. Assembly lines are typically made up of several stations, or workstations, where workers perform certain tasks.

It helps you make your operations more efficient

Conveyors are designed to make operations more efficient. They are usually long and narrow, so they take up less space in your factory.

This allows you to fit more conveyors on your factory floor so that you can move more materials throughout the day. Conveyors can also be used to transport materials to different workstations so that workers have everything they need close by.

That way, workers won’t have to walk across the factory to get supplies. This helps to save time, which can help improve production.

Warehouse Conveyors require very little human effort

If you’ve ever worked in a production facility, you know that it takes a lot of human effort to get things running smoothly.

It often takes a lot of time and effort to set up production lines, which can cause inefficiencies. Finding the right materials and equipment can take time, and workers may not always have everything they need nearby.

That’s where conveyors come in. Once you’ve installed the conveyor, you can set up production lines and make adjustments as necessary.

This helps to eliminate inefficiencies and keeps production running smoothly.

Conclusion

Warehouse conveyors are an important part of a production facility.

They are designed to help you move materials, as well as make your operations more efficient.

But there are many different types of conveyors, not just warehouse conveyors, but also conveyor tracks and gravity conveyors, so it’s important to understand the benefits of each one.

Once you’ve chosen the belt that best meets your facility’s needs, you can start enjoying the many benefits it has to offer.