The Backbone of Efficient Material Handling: How Steel Rollers Revolutionize Industries

In the fast-paced world of material handling, efficiency is key. And at the heart of every efficient operation lies a crucial component: steel rollers.

These unassuming cylindrical objects may seem insignificant, but they play a vital role in revolutionizing industries worldwide. From conveyor belts to assembly lines, steel rollers are the backbone of smooth and streamlined material handling processes.

Their durability, versatility, and cost-effectiveness make them indispensable in a wide range of industries, including manufacturing, logistics, and distribution.

Let’s explore how these simple yet powerful devices have transformed the way goods are moved, stored, and distributed.

We will delve into their design, construction, and the various applications where steel rollers shine. Get ready to discover the unsung heroes of material handling and uncover the secrets behind their unmatched performance.

Whether you are a business owner, a logistics professional, or simply curious about the inner workings of industries, this article will provide valuable insights into the world of steel rollers and their impact on efficiency.

Section 1: The role of steel rollers in material handling

Steel rollers serve as a pivotal component in material handling systems, enabling the smooth and efficient movement of goods throughout various stages of production and distribution.

They are commonly used in conveyor systems, where they facilitate the movement of items along a path, minimizing friction and allowing for easy transportation.

By reducing the effort required to move heavy loads, steel rollers enhance productivity and reduce the risk of injuries caused by manual handling.

These rollers act as a support system for conveyor belts, ensuring proper alignment and reducing belt tension, which ultimately leads to extended belt life and reduced maintenance costs.

Steel rollers also play a critical role in gravity conveyors, where they enable the flow of goods through inclined surfaces without the need for external power sources.

With their ability to withstand heavy loads and provide smooth movement, steel rollers are the unsung heroes of material handling, silently powering industries across the globe.

Section 2: Advantages of using steel rollers in industries

The use of steel rollers in material handling brings numerous advantages to industries. Firstly, steel rollers are known for their exceptional durability.

Made from high-quality steel, these rollers can withstand heavy loads, harsh environments, and continuous use without compromising their performance.

This durability translates into long-term cost savings, as businesses can rely on steel rollers to endure the rigors of daily operations without frequent replacements or repairs.

Additionally, steel rollers offer versatility in their applications. They can be customized to meet specific industry requirements, such as different diameters, lengths, and load capacities.

This versatility allows businesses to optimize their material handling systems for maximum efficiency. Moreover, steel rollers have a low coefficient of friction, reducing the amount of power required to move goods along conveyor systems.

This energy efficiency not only saves costs but also contributes to a greener and more sustainable operation. With their durability, versatility, and energy efficiency, steel rollers provide a solid foundation for efficient material handling processes.

Section 3: Types of steel rollers and their specific applications

Steel rollers come in various types, each designed to cater to specific material handling needs. One common type is the gravity roller, which relies on gravity to move goods along inclined surfaces.

Gravity rollers are widely used in warehouses and distribution centres, where they facilitate the flow of goods without the need for external power sources.

Another type is the driven roller, which is powered by an external motor or drive system. Driven rollers are commonly found in conveyor systems that require precise control over the movement of goods, such as assembly lines and automated warehouses.

These rollers can be easily integrated into existing systems, allowing businesses to upgrade their material handling processes without significant disruptions.

There are also conveyor rollers, which are used to support and guide conveyor belts. These rollers are essential for maintaining proper belt alignment and preventing belt damage or misalignment.

By understanding the different types of steel rollers and their specific applications, businesses can choose the most suitable option for their material handling requirements.

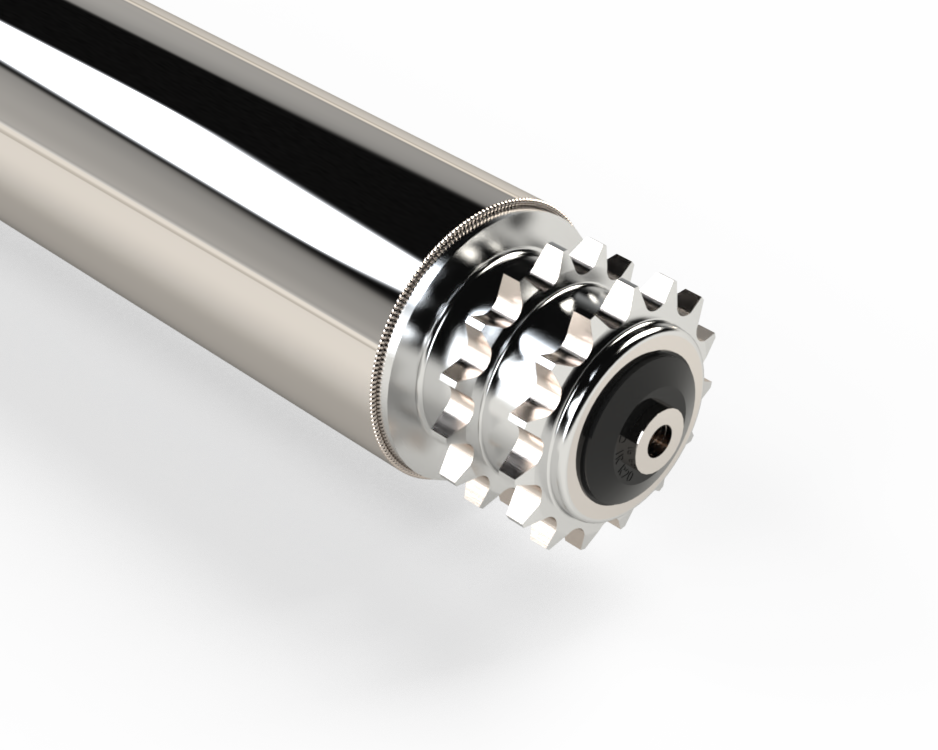

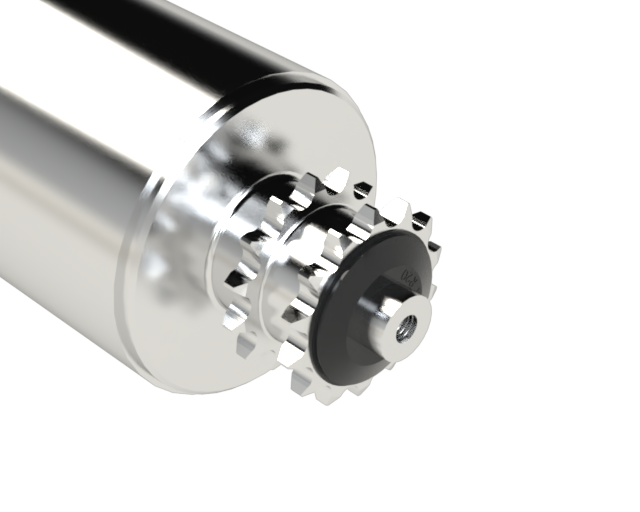

Section 4: The manufacturing process of steel rollers

The manufacturing process of steel rollers involves several steps to ensure their quality and performance. It typically begins with the selection of high-quality steel, chosen for its strength and durability. The steel is then cut into appropriate lengths and shaped into cylindrical forms.

Precision machining techniques are employed to create the necessary features, such as bearing housings and axle holes. These features are crucial for proper installation and smooth operation of the rollers.

Once the machining is complete, the rollers undergo a thorough cleaning and surface treatment process to remove any impurities and enhance their corrosion resistance.

Finally, the rollers are assembled with bearings and axles, and rigorous quality control checks are conducted to ensure their dimensional accuracy and overall performance.

The manufacturing process of steel rollers requires precision and attention to detail to deliver products that meet the demanding requirements of material handling applications.

Section 5: Factors to consider when choosing steel rollers for your industry

When selecting steel rollers for a specific industry, several factors must be taken into account to ensure optimal performance and longevity.

The load capacity of the rollers is a critical consideration, as it determines their ability to support the weight of the goods being transported. It is essential to choose rollers that can handle the anticipated load without compromising their structural integrity.

The speed at which goods will be moving along the conveyor system is another factor to consider. Higher speeds may require rollers with specialized bearings or additional features to ensure smooth operation and prevent excessive wear.

The environment in which the rollers will be used also plays a role in their selection. Harsh conditions, such as extreme temperatures or exposure to corrosive substances, may necessitate the use of rollers with specific coatings or materials to enhance their durability.

Finally, the compatibility of the rollers with existing conveyor systems should be evaluated to ensure seamless integration and minimize downtime during installation.

By considering these factors, businesses can choose steel rollers that are tailored to their specific industry requirements.

Section 6: Maintenance and care tips for steel rollers

Proper maintenance and care are crucial for maximizing the lifespan and performance of steel rollers. Regular inspections should be conducted to check for any signs of wear, such as uneven surfaces or damaged bearings.

Any damaged or worn-out rollers should be replaced promptly to avoid disruptions in material handling processes. Cleaning the rollers regularly is also essential, as it helps remove any debris or contaminants that may affect their performance. Lubrication is another critical aspect of roller maintenance.

Applying lubricants to the bearings and axles reduces friction and prevents premature wear. However, it is important to use the appropriate lubricant specified by the manufacturer to ensure compatibility and optimal performance.

Additionally, ensuring proper alignment and tension of conveyor belts can help prevent unnecessary strain on the rollers.

By following these maintenance and care tips, businesses can extend the lifespan of their steel rollers and maintain the efficiency of their material handling systems.

Section 7: Case studies showcasing the impact of steel rollers in different industries

The impact of steel rollers in various industries is best illustrated through real-life case studies. In the manufacturing industry, a company that produces automobiles implemented steel rollers in their assembly line to enhance efficiency.

By replacing outdated rollers with newer, more durable ones, they experienced a significant decrease in downtime due to roller failures, resulting in a boost in production output.

In the logistics sector, a distribution centre introduced steel rollers in their conveyor systems to handle an increased volume of goods.

The enhanced durability and load capacity of the steel rollers allowed them to handle the additional workload without compromising the speed and accuracy of their operations.

These case studies highlight the tangible benefits that steel rollers can bring to different industries, ultimately leading to improved productivity and cost savings.

Section 8: The future of steel rollers in material handling

As industries continue to evolve, so too will the role of steel rollers in material handling. Technological advancements, such as the Internet of Things (IoT) and automation, are expected to reshape the landscape of material handling systems.

Steel rollers will play a crucial role in supporting these advancements, providing the foundation for efficient and intelligent material handling processes.

The integration of sensors and data analytics into steel rollers will enable real-time monitoring and predictive maintenance, further enhancing their reliability and performance.

Additionally, advancements in materials science may lead to the development of even more durable and lightweight steel rollers, enabling higher load capacities and reducing energy consumption.

The future of steel rollers in material handling is undoubtedly bright, as these unassuming cylindrical objects continue to revolutionize industries and drive the efficiency of global supply chains.

Conclusion:

Steel rollers are the unsung heroes of material handling, silently powering industries and enabling the smooth and efficient movement of goods.

Their durability, versatility, and cost-effectiveness make them indispensable in a wide range of industries, from manufacturing to logistics and distribution.

The role of steel rollers in material handling cannot be underestimated, as they serve as the backbone of efficient operations.

By understanding the design, construction, and various applications of steel rollers, businesses can harness their power to optimize their material handling processes and achieve unprecedented levels of efficiency.

As industries continue to evolve, steel rollers will continue to play a vital role, supporting technological advancements and driving the future of material handling.

So, the next time you see a conveyor belt in action, remember the unsung heroes that make it all possible – the steel rollers.