The Benefits of Using Conveyor Rollers for Food & Vegetable Distribution

The food and vegetable distribution industry is constantly looking for ways to increase efficiency and productivity. One of the best ways to do this is through the use of conveyor rollers.

These food and vegetable rollers provide a safe and effective means of transporting products from one location to another. They are easy to install, durable and can help to reduce manual labour, which can lead to cost savings. Additionally, conveyor rollers can help to reduce product damage, making the entire distribution process more cost-efficient.

They can also be used in a variety of ways to improve the efficiency of the distribution process. This makes them an ideal choice for businesses in the food and vegetable distribution industry.

The Benefits of Using Conveyor Rollers for Food & Vegetable Distribution

The food and vegetable distribution industry is constantly looking for ways to increase efficiency and productivity. One of the best ways to do this is through the use of conveyor rollers. These rollers provide a safe and effective means of transporting products from one location to another.

They are easy to install, durable and can help to reduce manual labour, which can lead to cost savings. Additionally, conveyor rollers can help to reduce product damage, making the entire distribution process more cost-efficient.

They can also be used in a variety of ways to improve the efficiency of the distribution process. This makes them an ideal choice for businesses in the food and vegetable distribution industry.

What are Conveyor Rollers?

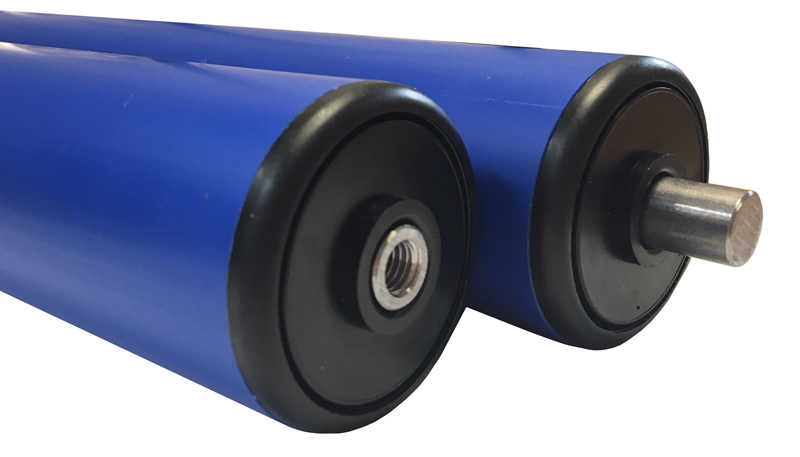

Conveyor rollers are a type of material handling equipment used in many industries. They are typically used to move items from one location to another in an efficient and cost-effective manner. Conveyor rollers are typically composed of several rotating cylinders that are connected to a frame.

The frame is then connected to a motor or other power source. This allows the rollers to move items along a conveyor belt. The rollers can be adjusted to different speeds and lengths to accommodate different products and their sizes.

Conveyor rollers are an ideal choice for many industries, including the food and vegetable distribution industry. They can help to increase efficiency, lower costs, reduce product damage, and make the entire process more efficient.

Additionally, conveyor rollers can be customized to meet specific needs and requirements. This allows businesses to tailor the equipment to meet their specific needs.

Benefits of Using Conveyor Rollers for Food & Vegetable Distribution

Conveyor rollers offer a number of benefits for businesses in the food and vegetable distribution industry. The most obvious benefit is that they reduce manual labour and increase efficiency. This not only saves time, but also helps to reduce costs associated with labour.

Additionally, conveyor rollers can help to reduce product damage, since items are moved along the conveyor belt in a controlled manner. This reduces the risk of product damage, which can lead to fewer losses and more profits.

Conveyor rollers also help to reduce the time it takes to move products from one location to another. This is especially important in the food and vegetable distribution industry, where time is of the essence.

Additionally, conveyor rollers can be used to transport a variety of products, from vegetables and fruits to meats and processed foods. This makes them an ideal choice for businesses that need to quickly and efficiently move a variety of products.

Finally, conveyor rollers can be used to improve the overall safety of the distribution process. By reducing manual labour and the risk of product damage, conveyor rollers can help to create a safer working environment.

This can lead to fewer injuries and less downtime, which can help to reduce costs associated with worker’s compensation and other related expenses.

Types of Conveyor Rollers Used in Food & Vegetable Distribution

There are several types of conveyor rollers that can be used in the food and vegetable distribution industry. These include gravity rollers, belt-driven rollers, and chain-driven rollers. Each type of roller has its own set of benefits and drawbacks, so it is important to choose the one that is best suited for your business.

Gravity rollers are the most common type of roller used in the food and vegetable distribution industry. They are simple, cost-effective, and easy to install. They are typically used to move lightweight items, such as fruits and vegetables. They can also be used for heavier items, but this requires a more powerful motor.

Belt-driven rollers are similar to gravity rollers, but they are powered by a motor. This allows them to move heavier items, such as meats and processed foods. They are typically more expensive than gravity rollers, but they can help to increase efficiency and reduce product damage.

Chain-driven rollers are the most powerful type of roller and are typically used for heavier items. They are the most expensive type of roller, but they are also the most durable and can handle the most heavy-duty loads.

How to Choose the Right Conveyor Rollers for Your Business

Choosing the right conveyor rollers for your business can be a challenging task. It is important to consider the type of products you will be moving and the size and weight of those products. Additionally, it is important to consider factors such as cost, durability, and ease of installation.

Taking all of these factors into account can help you to make the best decision for your business.

Once you have determined the type of conveyor rollers that you need, you should also consider the type of motor that will be used.

This is important because it will affect the power and speed of the roller. Additionally, you should consider the type of material that the rollers will be made from. This can affect the durability and cost of the rollers.

Maintenance Tips for Conveyor Rollers

Regular maintenance is an important part of owning and operating any type of conveyor roller. This is because regular maintenance can help to extend the life of the rollers and ensure that they operate smoothly and efficiently. There are a few maintenance tips that you should keep in mind when caring for your rollers.

First, it is important to make sure that the rollers are properly lubricated. This will help to reduce friction and wear, which can extend the life of the rollers. Additionally, it is important to make sure that the rollers are cleaned regularly to remove any debris or dirt that may have accumulated on the rollers.

Second, it is important to inspect the rollers regularly to ensure that they are operating properly. This can help to identify any potential problems before they become serious.

If there are any issues, it is important to address them as soon as possible to prevent further damage.

Finally, it is important to make sure that the rollers are properly aligned. This will help to ensure that the rollers are moving smoothly and that they are not at risk of being damaged by uneven surfaces.

Also, it is important to check the rollers for any signs of wear and tear. If any of the rollers are showing signs of wear and tear, they should be replaced to ensure that they are operating properly.

Examples of Successful Conveyor Rollers Applications in Food & Vegetable Distribution

Conveyor rollers have been successfully used in a variety of food and vegetable distribution applications. For example, in the retail sector, conveyor rollers are often used to move products from the backroom to the sales floor. Additionally, they can be used to move products from the warehouse to the loading dock, which can help to reduce the time and cost associated with manual labour.

In the food processing industry, conveyor rollers are used to move food items from the production area to the packaging area. This helps to ensure that the food items are moved quickly and efficiently and that they are not damaged in the process.

Furthermore, conveyor rollers are used to move food items from one location to another within the processing facility. This can help to reduce the time and cost associated with manual labour.

Finally, in the agricultural sector, conveyor rollers are often used to move fruits and vegetables from the farm to the processing facility. This helps to reduce the time and cost associated with manual labour and can help to increase the efficiency of the entire process.

Conclusion

Conveyor rollers are an ideal solution for businesses in the food and vegetable distribution industry. They can help to increase efficiency, reduce costs, and improve safety. Additionally, they can be customized to meet specific needs and requirements.

When choosing conveyor rollers for your business, it is important to consider factors such as cost, durability, ease of installation, and the type of product you will be moving. Additionally, it is important to make sure that the rollers are properly maintained and inspected on a regular basis.

By taking all of these factors into consideration, you can ensure that you are getting the most out of your conveyor rollers.