Streamlining Your Warehouse Operations: The Benefits of Floor Conveyor Pallet Tracks

Warehouse operations are a crucial aspect of any business that deals with physical products. Efficient operations are key to success, and that’s where floor conveyor pallet tracks come into play.

These tracks are designed to streamline the movement of goods in your warehouse, making it easier to manage inventory, reduce labour costs, and increase productivity.

By implementing floor conveyor pallet tracks, you can create a more efficient workflow that maximizes space utilization and minimizes errors.

In this article, we’ll take a closer look at the benefits of floor conveyor pallet tracks and how they can help you optimize your warehouse operations.

Whether you’re a small business or a large corporation, improving your warehouse operations can have a significant impact on your bottom line. So, let’s dig in and explore the advantages of floor conveyor pallet tracks!

What are floor conveyor pallet tracks?

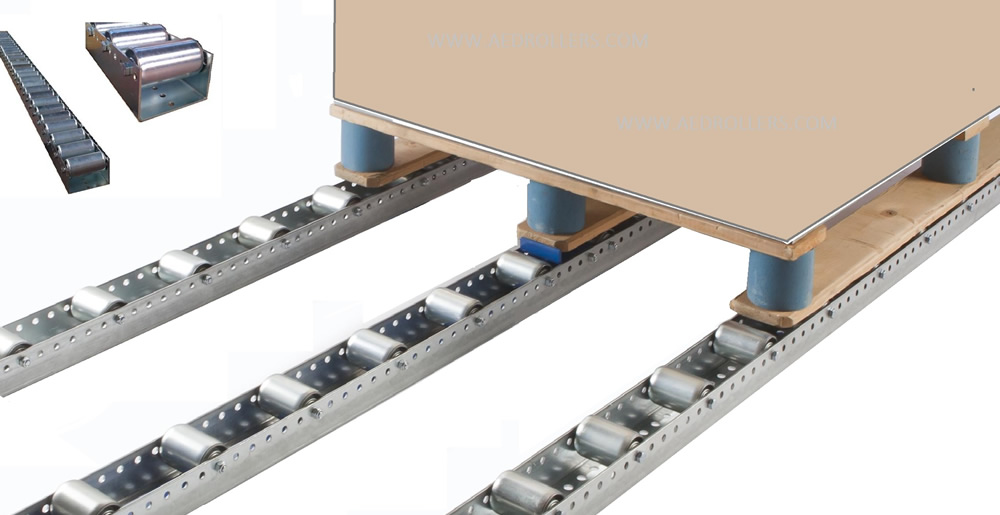

Floor conveyor pallet tracks are a type of automated material handling system that utilizes a network of floor-mounted tracks to move pallets and other heavy loads throughout a warehouse.

These tracks are typically made of steel and are designed to withstand the weight of heavy loads. The pallets are placed on the tracks, which are then moved by a series of motors and rollers.

The tracks can be configured to move in multiple directions, allowing for the efficient movement of goods throughout the warehouse.

One of the key advantages of floor conveyor pallet tracks is their ability to move heavy loads without the need for manual labour. This not only reduces the risk of workplace injuries, but it also allows for faster and more efficient movement of goods.

Additionally, the tracks can be configured to move at different speeds, allowing for greater control over the movement of goods and reducing the risk of damage to products.

Benefits of using floor conveyor pallet tracks

There are many benefits to using floor conveyor pallet tracks in your warehouse operations. Here are just a few:

Increased productivity

Floor conveyor pallet tracks can significantly increase productivity in your warehouse. By automating the movement of goods, you can reduce the time it takes to move products from one location to another.

This means that your employees can focus on other tasks, such as inventory management or order fulfilment. Additionally, the tracks can be programmed to move at specific speeds, allowing for faster movement of goods when time is of the essence.

Improved accuracy

Floor conveyor pallet tracks can also improve the accuracy of your warehouse operations. Because the movement of goods is automated, there is less room for human error. This can help reduce errors in order fulfillment, inventory management, and other critical areas of your warehouse operations.

Reduced labour costs

By automating the movement of goods, floor conveyor pallet tracks can help you reduce labour costs. This is because you won’t need as many employees to move goods throughout your warehouse.

Additionally, automated material handling systems can work 24/7, meaning that you can increase your output without having to hire additional employees.

Space utilization

Another benefit of floor conveyor pallet tracks is their ability to maximize space utilization in your warehouse. Because the tracks are located on the floor, they don’t take up valuable vertical space like other material handling systems.

This means that you can store more products in the same amount of space, increasing your storage capacity and reducing the need for additional warehouse space.

Types of floor conveyor pallet tracks

There are several different types of floor conveyor pallet tracks available on the market. Here are a few of the most common:

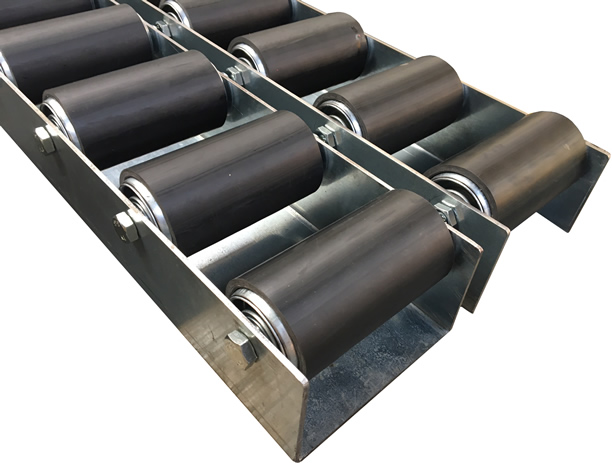

Chain conveyor pallet tracks use a series of chains to move pallets and other heavy loads throughout a warehouse. The chains are powered by motors and rollers, allowing for the efficient movement of goods. Chain conveyor pallet tracks are ideal for heavy-duty applications and can be configured to move in multiple directions.

Roller conveyor pallet tracks

Roller conveyor pallet tracks use a series of rollers to move pallets and other heavy loads throughout a warehouse. The rollers are powered by motors, allowing for the more efficient movement. Roller conveyor pallet tracks are ideal for applications where products need to be moved quickly and efficiently.

Belt conveyor pallet tracks

Belt conveyor pallet tracks use a series of belts to move pallets and other heavy loads throughout a warehouse. The belts are powered by motors and can be configured to move in multiple directions. Belt conveyor pallet tracks are ideal for applications where products need to be moved gently, such as in the food and beverage industry.

How to choose the right floor conveyor pallet track for your warehouse

Choosing the right floor conveyor pallet track for your warehouse can be a daunting task. Here are a few things to consider when making your decision:

Load Capacity: One of the most important factors to consider when choosing a floor conveyor pallet track is the load capacity. You’ll want to choose a track that can support the weight of your heaviest loads. Additionally, you’ll want to consider the size and shape of your pallets to ensure that they will fit on the track.

Speed: Another important factor to consider is the speed of the track. You’ll want to choose a track that can move your products efficiently without causing damage. Additionally, you may want to consider a track that can be programmed to move at different speeds depending on the needs of your operation.

Configuration

Floor conveyor pallet tracks can be configured in many different ways to suit your warehouse’s specific needs. You’ll want to consider the layout of your warehouse and the types of products you’ll be moving when choosing a configuration.

Finally, you’ll want to consider the maintenance requirements of the track when making your decision. You’ll want to choose a track that is easy to maintain and repair, minimizing downtime and maximizing productivity.

Installation and maintenance of floor conveyor pallet tracks

Installing and maintaining floor conveyor pallet tracks requires specialized knowledge and expertise. It’s important to work with a qualified professional to ensure that your tracks are installed correctly and maintained properly.

Here are a few things to keep in mind:

Installation: During installation, the tracks will need to be carefully positioned and secured to ensure that they can support the weight of heavy loads. Additionally, the motors and rollers will need to be installed and connected to the tracks. It’s important to work with a qualified professional to ensure that the installation is done correctly.

Maintenance: Regular maintenance is essential to keep your floor conveyor pallet tracks running smoothly. This may include lubricating motors and rollers, inspecting the tracks for damage, and replacing worn or damaged parts.

It’s important to work with a qualified professional to ensure that your tracks are properly maintained and repaired when necessary.

Case studies: Successful implementation of floor conveyor pallet tracks

There are many examples of businesses that have successfully implemented floor conveyor pallet tracks in their warehouse operations. Here are a few:

Amazon: Amazon is one of the largest users of floor conveyor pallet tracks in the world. The company uses a network of tracks to move products throughout its massive warehouses, allowing for efficient and accurate order fulfillment.

Coca-Cola: Coca-Cola uses floor conveyor pallet tracks to move products through its bottling plants. This allows the company to maximize space utilization and reduce labor costs while maintaining high levels of accuracy and efficiency.

Toyota: Toyota uses floor conveyor pallet tracks in its manufacturing plants to move products and materials throughout the production process. This allows for efficient and accurate production, reducing the risk of errors and increasing productivity.

Common misconceptions about floor conveyor pallet tracks

There are several common misconceptions about floor conveyor pallet tracks. Here are a few:

They’re expensive

While it’s true that floor conveyor pallet tracks can be expensive to install, they can also save you money in the long run by reducing labour costs, minimizing errors, and increasing productivity.

They’re difficult to maintain

While floor conveyor pallet tracks do require regular maintenance, they are designed to be easy to maintain and repair. Additionally, working with a qualified professional can help ensure that your tracks are properly maintained and repaired when necessary.

They’re only for large businesses

While it’s true that many large businesses use floor conveyor pallet tracks, they can also be beneficial for small and medium-sized businesses. By streamlining your warehouse operations, you can increase productivity and reduce costs, regardless of the size of your operation.

Future of warehouse automation with floor conveyor pallet tracks

The future of warehouse automation is bright, and floor conveyor pallet tracks are sure to play a major role. As technology continues to evolve, we can expect to see even more advanced and efficient material handling systems that will further streamline warehouse operations and maximize productivity.

Conclusion: Streamlining your warehouse operations with floor conveyor pallet tracks

Floor conveyor pallet tracks are a powerful tool for streamlining your warehouse operations. By automating the movement of goods, you can increase productivity, reduce labour costs, and improve accuracy.

Additionally, floor conveyor pallet tracks can help you maximize space utilization and reduce the risk of workplace injuries. If you’re looking to optimize your warehouse operations, floor conveyor pallet tracks are definitely worth considering.