Exploring Roller Types Used in Conveyors: What You Need to Know

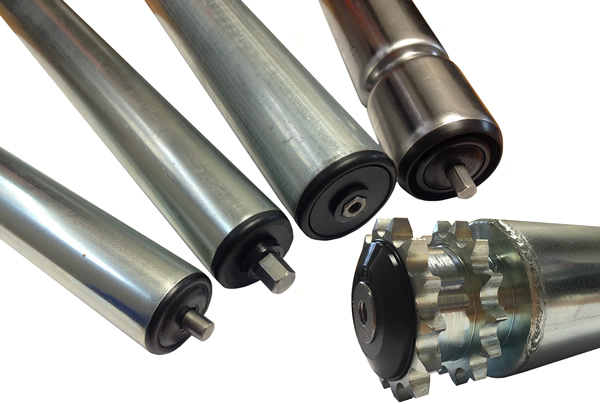

Roller conveyors are an essential component in many industrial applications, as they provide a reliable way to move goods from one place to another.

Depending on the type of goods being transported, there are a variety of roller types that can be used to ensure the goods move safely and securely along the conveyor.

The type of roller used will depend on the load capacity, speed, and accuracy requirements. Understanding the different roller types and their benefits can help you make the right decision when selecting a conveyor system.

Let’s learn more about the types of rollers used in conveyors, their features, and what you need to consider when making your selection.

Types of Rollers Used in Conveyors

There are a variety of different roller types used in conveyors, and each one comes with its own set of benefits. By understanding the different roller types, you will be able to select the best roller type to suit your application. Let’s take a look at each one.

Trough Rollers – Trough rollers are used in conveyor systems with heavier loads. They’re perfect for moving bulk materials like coal, grain, or sand because they can support heavier loads while also allowing a bit of flexibility. The trough design is longer than a conventional roller, allowing it to accommodate larger and heavier materials. The trough roller is especially useful in situations where a finger roller may not be able to support the heavier load.

Impact Rollers – Impact rollers are designed to handle heavier loads than finger rollers, but have a lower capacity than trough rollers.

They are often used for bulk materials like gravel, sand, or coal. Impact rollers are also a good option if you are transporting products that can sometimes jam in a trough roller.

If you need to keep material flowing smoothly, but don’t need the extra capacity of a trough roller, the impact roller is a great option.

Gravity Rollers – Gravity rollers are designed for lighter loads, such as paper or cardboard. They are sometimes called “friction rollers” because they use friction to create the drive.

Gravity rollers are a good option if you need to move smaller loads that don’t require a lot of power.

Grooved Rollers – Grooved rollers are a great option for very light loads, such as small sheets of paper, or lightweight materials like fertilizers or chemicals.

Grooved rollers use a slot in the entire length of the roller to grab and pull the material. They are a good option if you need to move very light materials, but don’t want to use friction rollers.

While they are a great option for lighter loads, they do have a lower load capacity than other types of rollers.

Factors to Consider When Choosing a Roller Type

When selecting the best roller type for your application, you want to consider the load capacity, speed, and accuracy requirements. You also want to take into account the environment you will be operating in, to ensure the rollers can withstand the conditions.

To select the best roller type, you need to look at each factor individually and then decide which roller type will best meet your needs. Let’s take a look at each one.

Load Capacity – Before you can decide which roller type to use, you need to know the maximum load capacity your conveyor will be required to handle.

Depending on the material being transported, you may need a roller type that can support a heavier load. When selecting a roller type, you will also need to factor in the size of the material being transported.

The bigger the piece of material, the heavier it will be, and the more capacity your roller type will need to handle the load.

Speed – Next, you need to consider the speed requirements for your conveyor. You may need to select a faster roller type if you need the material to move quickly.

Likewise, if you want the material to move slowly, you want to select a roller type that moves slower. You also need to take into account the material being transported and whether it will diminish the speed of the roller.

Accuracy – The accuracy requirements for your conveyor will also play a role in selecting the best roller type. If you need the material to be transported with a high level of accuracy, you need to be sure that your roller type can meet those requirements.

Environment – You also need to take into account the environment where the conveyor will be operating. Some roller types are better suited for harsh environmental conditions than others, so you need to select a roller type that will stand up to the conditions.

Conclusion

There are a variety of different roller types used in conveyors, and each one comes with its own set of benefits. By understanding the different roller types, you will be able to select the best roller type to suit your application. Let’s take a look at each one.

First, you have the trough roller. Trough rollers are used in conveyor systems with heavier loads.

They’re perfect for moving bulk materials like coal, grain, or sand because they can support heavier loads while also allowing a bit of flexibility. The trough design is longer than a conventional roller, allowing it to accommodate larger and heavier materials.

Next, you have the impact roller. Impact rollers are designed to handle heavier loads than finger rollers, but have a lower capacity than trough rollers.

They are often used for bulk materials like gravel, sand, or coal. Impact rollers are also a good option if you are transporting products that can sometimes jam in a trough roller.

If you need to keep material flowing smoothly, but don’t need the extra capacity of a trough roller, the impact roller is a great option.

Last, you have the gravity roller. Gravity rollers are designed for lighter loads, such as paper or cardboard. They are sometimes called “friction rollers” because they use friction to create the drive.

Gravity rollers are a good option if you need to move smaller loads that don’t require a lot of power.